Flange Marking Machine: Enhancing Efficiency and Accuracy in Industrial Marking

Introduction

Flanges are essential components in a wide range of industries, from oil and gas to manufacturing and construction. As critical parts for connecting pipes, valves, and other equipment, flanges must be marked with specific details to ensure quality control, traceability, and compliance with regulatory standards. This is where the flange marking machine comes in, offering precise, durable, and efficient marking solutions for flanges of various sizes and materials. This article explores the importance, types, and benefits of flange marking machines, as well as the factors to consider when choosing the right machine for your operations.

Why Flange Marking is Important

Proper markings on flanges ensure that they meet quality standards, regulatory requirements, and safety protocols. Here are some key reasons why flange marking is critical:

1. Quality Control and Traceability

Flange markings typically include essential information such as part numbers, dimensions, material specifications, manufacturing dates, and batch numbers. This helps ensure that each flange is traceable throughout its lifecycle. In industries such as oil and gas, traceability is vital for identifying potential defects, handling recalls, and maintaining product integrity.

2. Compliance with Standards

Flanges used in critical industries, like oil and gas, must meet various safety and quality standards. Regulatory bodies such as ASME (American Society of Mechanical Engineers) and ISO (International Organization for Standardization) require that flanges be marked with specific information to ensure they meet industry standards. A flange marking machine ensures that these standards are consistently met, avoiding any legal or safety-related issues.

3. Preventing Misidentification

Properly marked flanges help prevent misidentification, which is essential for installation, maintenance, and repairs.. Marking also helps to minimize human error, reducing the likelihood of using the wrong component in critical systems.

Read also: Swag Essentials Shark Tank Net Worth: Business’s Financial Success

4. Streamlining Operations

With proper markings, flange manufacturers and users can quickly identify important details about the flanges, such as their size, material, and specifications. This not only speeds up the installation process but also improves inventory management and simplifies quality control procedures.

Types of Flange Marking Machines

Several types of flange marking machines are available, each offering unique features and benefits. The choice of machine depends on factors such as production volume, flange material, and marking requirements.

1. Dot Peen Marking Machines

These machines use a stylus or pin that impacts the surface of the flange, creating a series of dots that form readable text and numbers.

Advantages:

- Durability: The markings are deeply etched into the flange surface, making them resistant to wear and corrosion.

- Versatility: Dot peen marking machines can be used on a wide variety of materials, including steel, aluminum, and other alloys commonly used in flange manufacturing..

2. Laser Marking Machines

Laser marking machines use high-powered lasers to engrave permanent marks on the surface of flanges. This method is highly accurate and produces precise, clean markings that can withstand harsh conditions.

Advantages:

- Precision: Laser marking machines offer high-precision engraving, making them suitable for applications where fine details are necessary.

3. Inkjet Printing Machines

Inkjet printing machines use specialized ink to print markings on the surface of flanges. This is a non-contact method, making it quick and effective for high-volume production environments.

Advantages:

- Speed: Inkjet printing is one of the fastest marking methods, making it ideal for high-volume production.

- Flexibility: Inkjet printers can easily print variable data, such as part numbers or serial numbers, on each flange.

- Cost-effective: Inkjet printing machines are relatively inexpensive and easy to maintain.

4. Rotary Engraving Machines

Rotary engraving machines use a rotating cutter to engrave markings on the surface of flanges. This method is highly durable and produces deep, permanent marks.

Advantages:

- Deep markings: Rotary engraving creates deep and durable markings, which are resistant to wear and tear.

- Precision: This method allows for highly detailed markings, ensuring legibility and clarity.

- Versatility: Rotary engraving can be used on a wide range of flange materials, including hard metals.

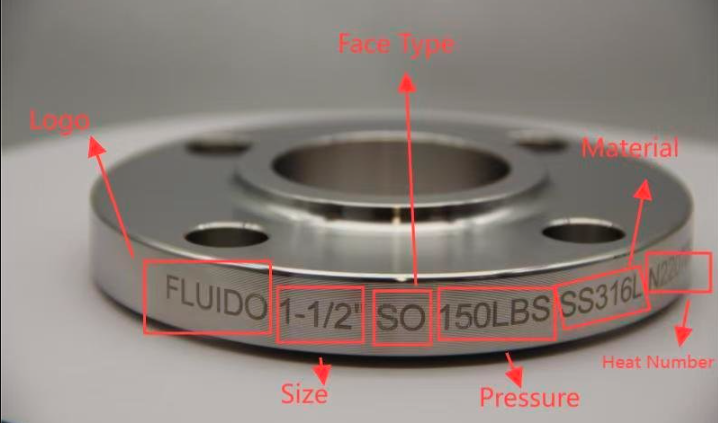

Key Information to Mark on Flanges

Flanges are marked with a variety of information, depending on the industry and the specific application. The following details should be included to ensure proper identification, traceability, and compliance:

1. Part Number

Each flange should have a unique part number that helps to identify it from other components. The part number typically includes details about the flange’s size, material, and specifications.

2. Material Specifications

It is important to mark the material type on the flange, such as stainless steel, carbon steel, or alloy, to ensure that the right material is used for the right application. This is particularly important for industries like oil and gas, where material strength and durability are critical.

Conclusion

Using a flange marking machine provides manufacturers with a precise, efficient, and cost-effective solution for marking flanges with critical information. Whether through dot peen marking, laser engraving, or inkjet printing, the right marking machine can enhance operational efficiency, improve safety, and ensure compliance with industry standards. By choosing the right machine and considering factors like material type, production volume, and marking requirements, businesses can ensure their flange marking process is accurate and reliable.